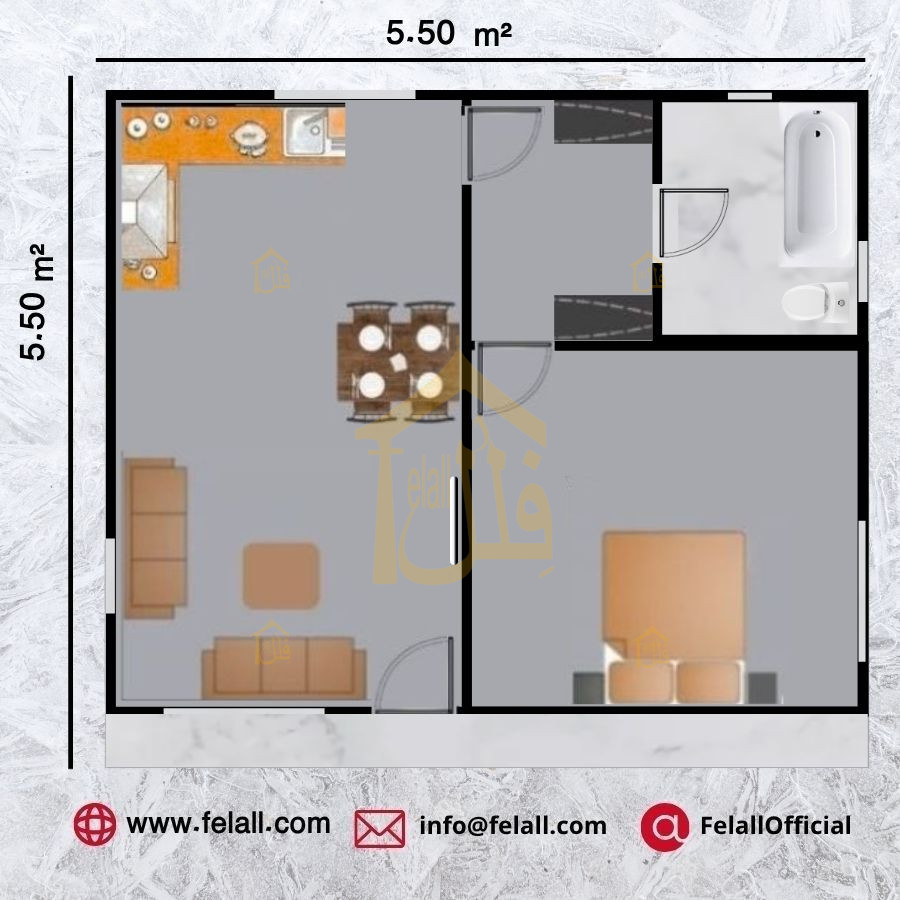

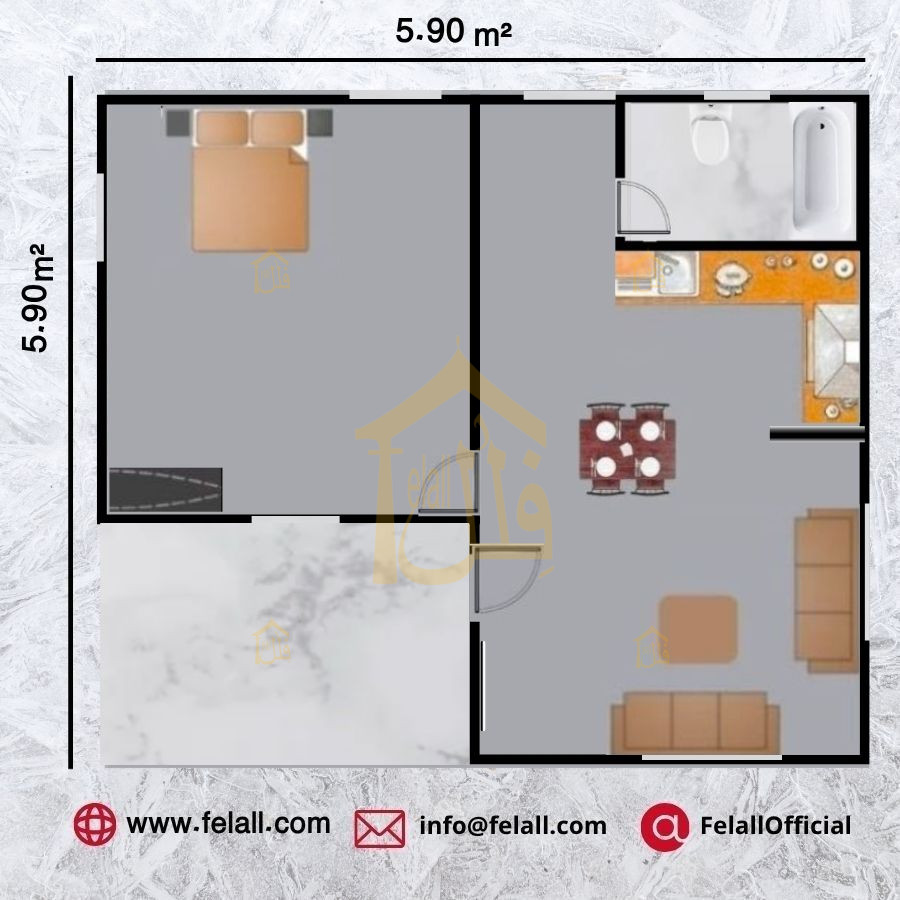

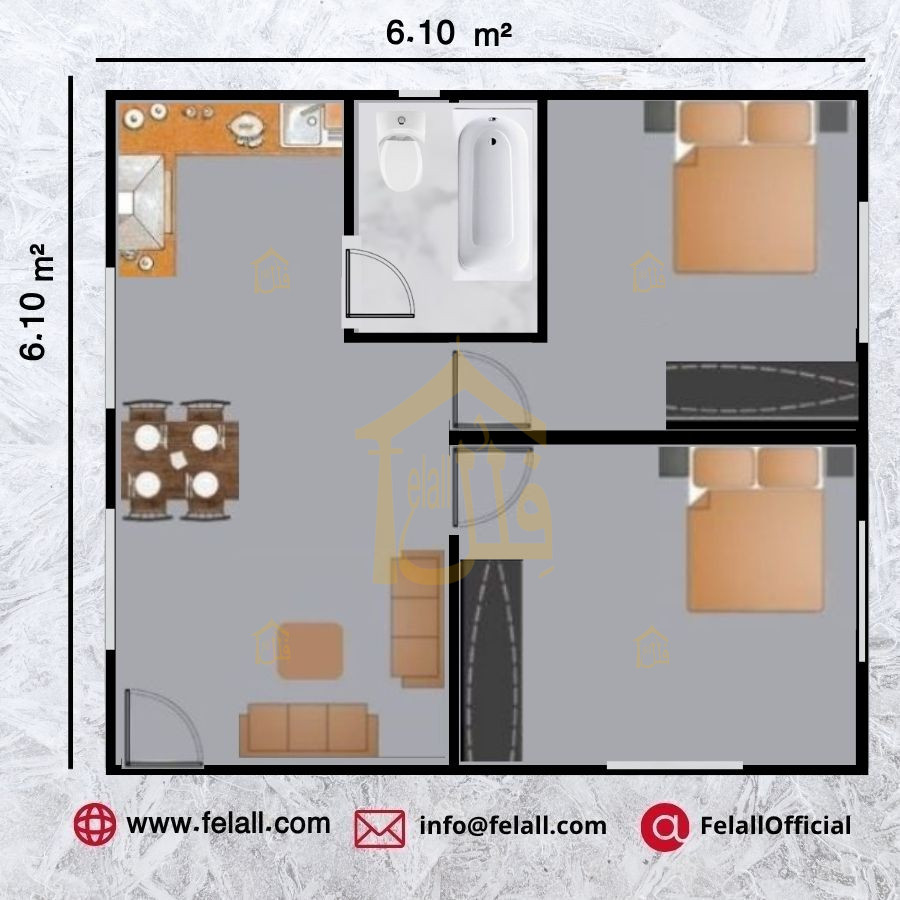

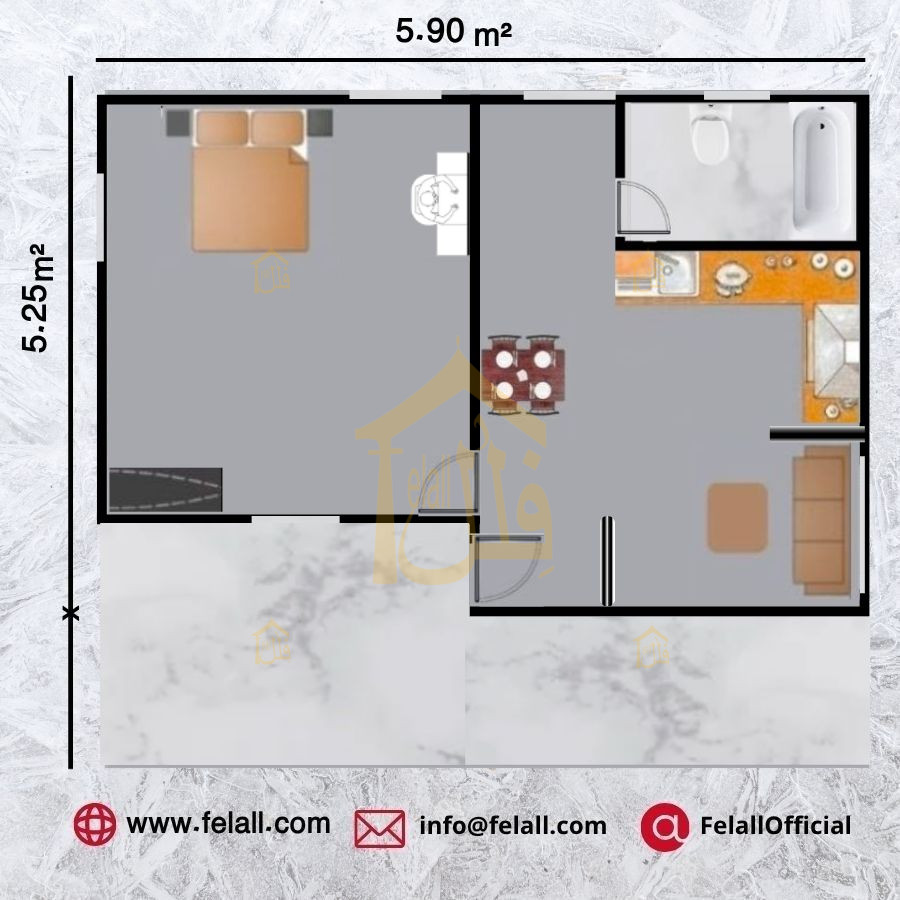

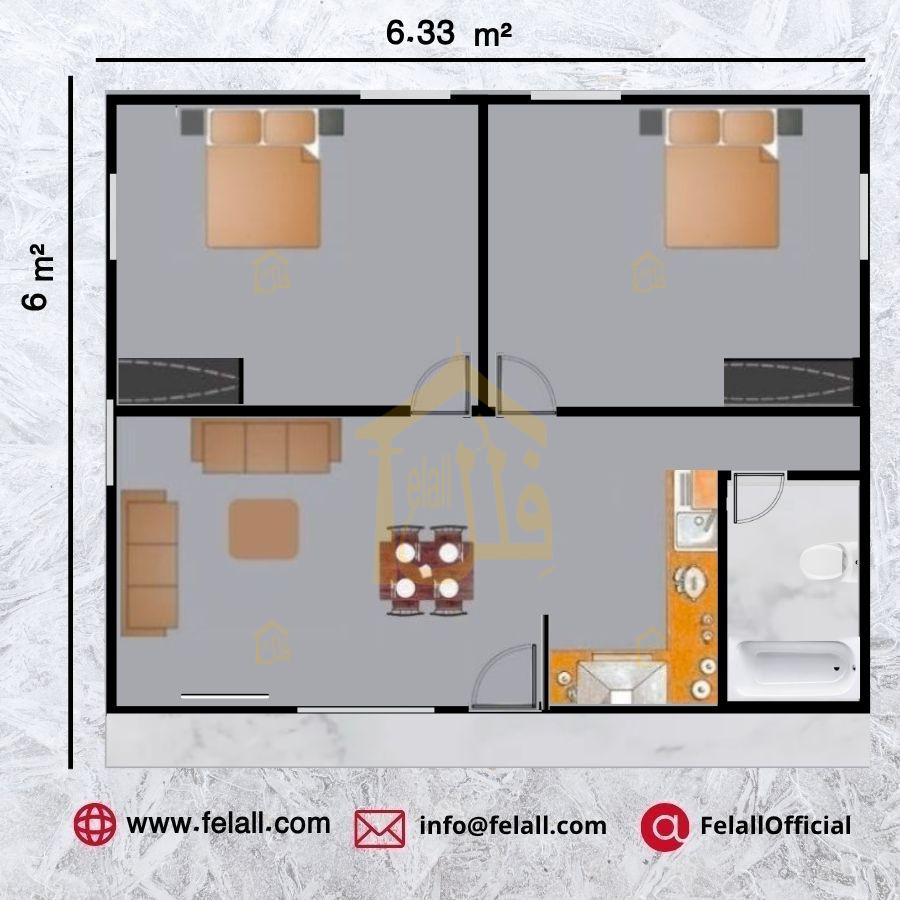

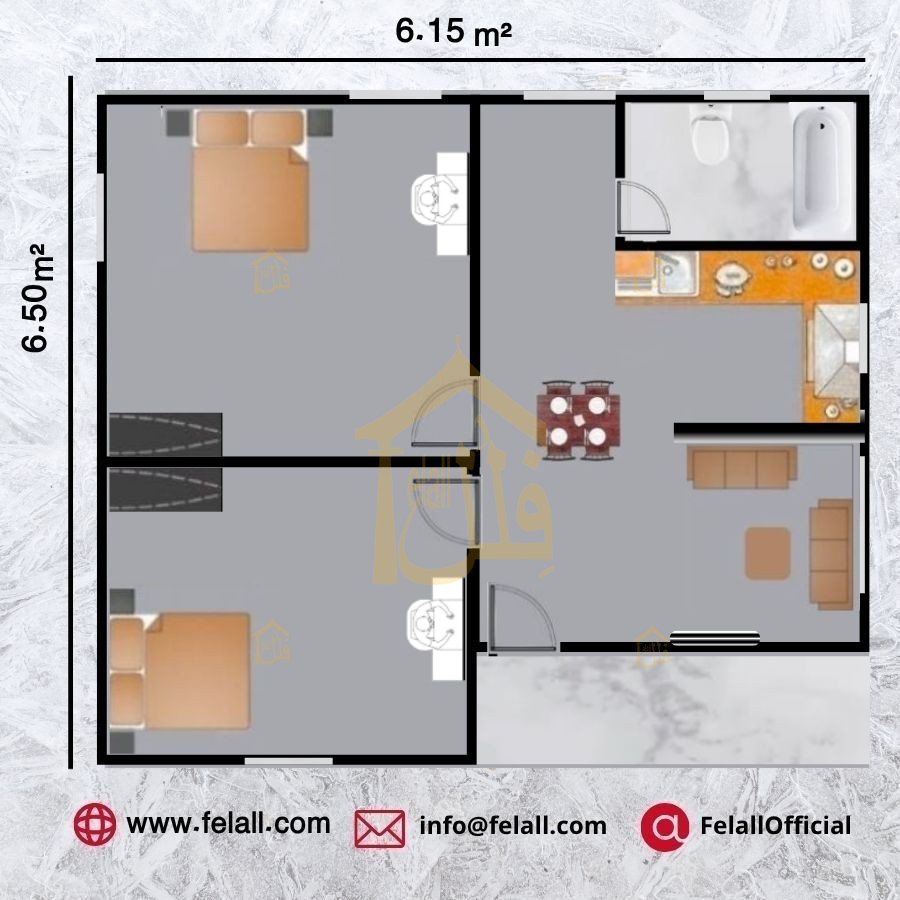

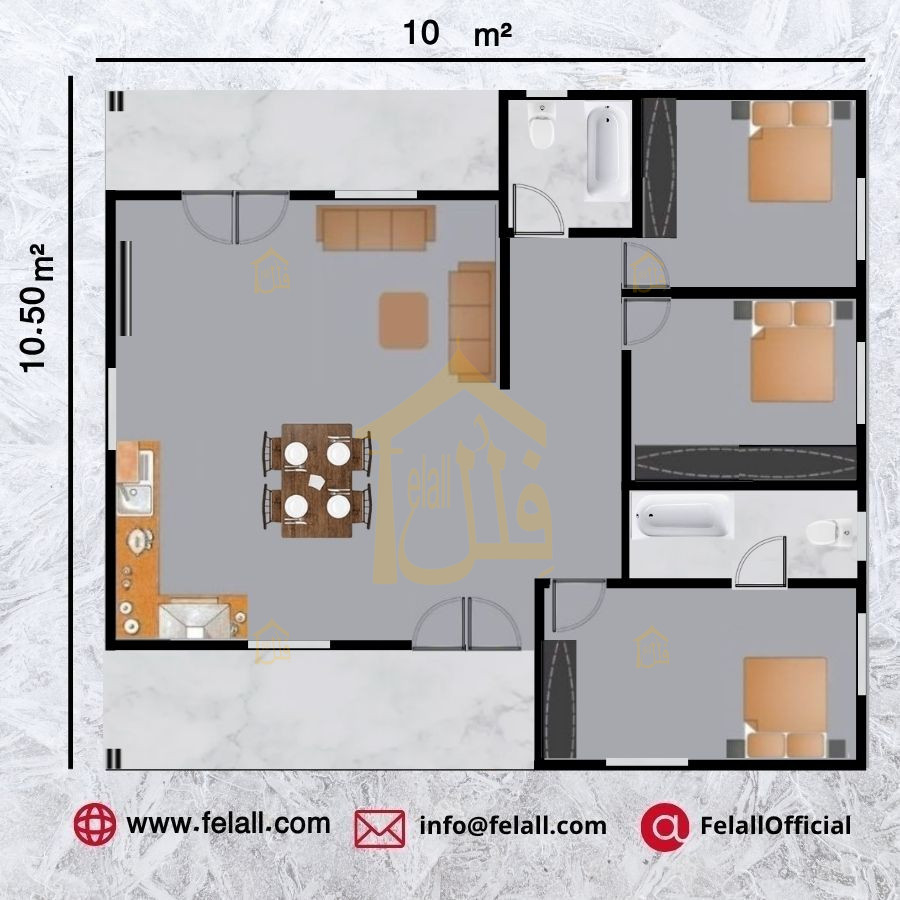

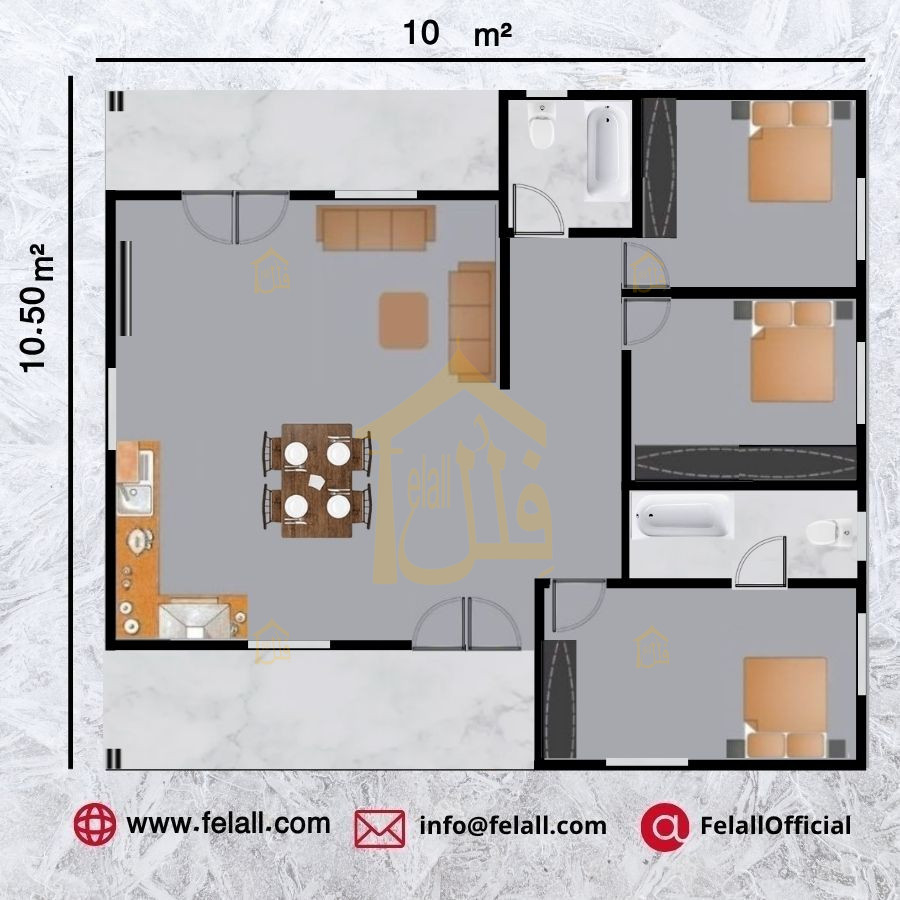

105 m² Prefabricated House

-

$16,500.00

-

$16,500.00

-

$16,500.00

-

$16,500.00

-

$16,500.00

-

$6,598.90

Reviews & Ratings

105 m² Prefabricated House

Prepare to move into a simple and beautiful home featuring a modest porch and a sloping roof. This home features two bedrooms, two bathrooms, and an open kitchen, ensuring a comfortable family life. This single-story home offers everything you need in a prime location.

Advantages of Buying a Prefabricated House from Us

1. Optimum Use of Space: When designing a house project, we pay special attention to design by rationally using every square meter of small spaces. In our house projects, we provide the best living conditions and pay attention to the smallest details. We believe that a spacious and functional environment can be created even in small spaces, and our houses are proof of this.

2. Environmentally Friendly Materials: Environmental focus is the cornerstone of our work. We attach special importance to using environmentally friendly and renewable materials in the production of our small modular houses. We aim to minimize our negative impact on the environment and use materials such as waste paper and reusable or recycled wood efficiently. For houses, we can use off-grid systems, taking into account individual needs and resources.

3. "Eco-Friendly Small House Factory" houses do not require additional air conditioning, air recovery or maintenance costs for unnecessary equipment. Thanks to a well-designed insulation system and the use of energy-efficient materials, you will save on heating costs. The lightweight structure of the house does not require a large and expensive foundation, which significantly reduces construction time and costs.

4. Excellent moisture control. A carefully designed wooden structure and natural materials do not require the use of metal profiles and synthetic membranes that prevent condensation and moisture accumulation inside the structure, which can lead to mold and rot in the walls. This allows us to create houses with excellent moisture control, allowing our customers to enjoy a comfortable indoor environment that promotes a healthy and high-quality life.

Frequently Asked Questions1. What is included in your price?

Preparation and installation of prefabricated housing materials. Preparation of painting materials. Preparation and installation of internal and external windows and doors. Preparation and installation of electrical and plumbing installations.

2. What does the customer need to do?

Concrete floor and all kinds of excavation, floor and wall coverings (cement, ceramic, parquet, tiles, etc.), external connections outside the prefabricated building (electricity, sewage and clean water), permits and licenses to be obtained from the municipality, heating and cooling facilities (heater, air conditioner, etc.), food and accommodation expenses of the assembly team, transportation and transportation insurance are the responsibility of our customers.

3. Can you produce prefabricated houses anywhere?

Our service is available worldwide. The buyer covers the accommodation and food expenses of the assembly and painting teams. (The assembly team consists of 5 people, and the painting team consists of 2 people.)

4. Is a license required to build a prefabricated house?

Licensing is initiated by the municipality of the region where the prefabricated house will be built. In order to obtain a license, the customer is responsible for preparing the architectural, structural, mechanical and electrical project by the architectural offices. The customer is responsible for the license and all other legal permissions.

5. How is heat and sound insulation of prefabricated houses done?

The outer wall thickness used in prefabricated houses is 10 cm. The 8 cm thick polystyrene foam with a density of 16 kg/m³ between the wall panels and the 10 cm thick mineral wool used for roof insulation provide significantly better heat and sound insulation than a traditional reinforced concrete building.

6. How long is the lifespan of prefabricated houses?

The wall materials used in prefabricated houses are bitumen and fiber cement. The load-bearing system of the building and all metal parts in contact with the exterior are galvanized and thus resistant to rust. The average lifespan of prefabricated houses is between 45 and 50 years.

7. Are prefabricated houses used only in summer?

Prefabricated houses are equipped with an insulation system that allows them to be used throughout the year. Buildings suitable for all types of climatic conditions can be produced. Production takes into account the climatic characteristics of the place where the buildings will be built.

8. How many floors can prefabricated houses be built at most?

They can be built as single or double storey.

9. Can they be built on top of a reinforced concrete building?

They can only be built on top of single-story reinforced concrete buildings. The building below must have a solid, flat roof.

10. Can a building with the layout and appearance we want be built?

As long as it is compatible with the prefabricated building system, the appearance and order we want can be achieved.

11. How many days does it take to deliver a prefabricated house on average?

Depending on the size of the prefabricated house you choose and the density of the factory, a single-story house of 100 square meters is delivered in an average of 15-20 business days. Assembly is completed in an average of 7 days, and painting is completed in 3 days.

12. What vehicles can transport prefabricated houses?

Prefabricated houses can be transported by truck, international road transport, ship or train. A medium-sized wooden truck of 7 meters in length can carry 70 square meters of prefabricated building material. The average total weight varies between 7 and 8 tons.

13. Are prefabricated houses earthquake resistant?

It should not be forgotten that prefabricated houses are created as earthquake-resistant structures. Since they are much lighter than reinforced concrete structures and the disassembled parts are connected to each other with steel bolts, they flex during an earthquake but do not collapse.

14. Can prefabricated houses be disassembled and reassembled elsewhere?

If you pay the disassembly and reassembly costs, you can disassemble your house and reassemble it in a different location at any time.

15. What is your payment method?

80% of the contract price is collected in advance from the contract date, and the remaining 20% is collected in advance during loading.

Planning

Start by planning where and how many windows and doors you'll place. How will you navigate your home? For example, do you want the entryway to connect directly to the main room from the front, or would you prefer the entryway on the long side? For windows, you might want a large glass partition in the living room to connect it to the patio or surrounding areas. Or do you want to create a more private atmosphere with less visibility? Once you have a clearer idea of how your home will be used, making decisions about windows and doors becomes easier. It doesn't get much more difficult than that. We welcome you to contact our experts to discuss your ideas.

Frequently Bought Products

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

$16,500.00

-

$16,500.00

-

$16,500.00

-

$16,500.00

-

$16,500.00

-

$6,598.90

about us

You could say we started from scratch, but our craftsmanship has made us one of the first companies to manufacture and produce prefabricated homes and their accessories that are suitable for the climate.